Driving Lights on an F650GS, Page 5 |

Top Page 1 Page 2 Page 3 Page 4 Page 5 Page 6 Page 7 Page 8 Page 9 Page 10

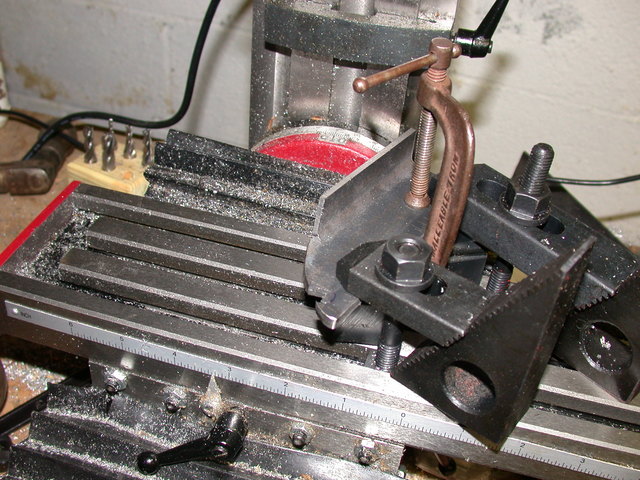

Machining time. I have a minimill, and so help me I'm gonna use it. First I cleaned up some of the surfaces.

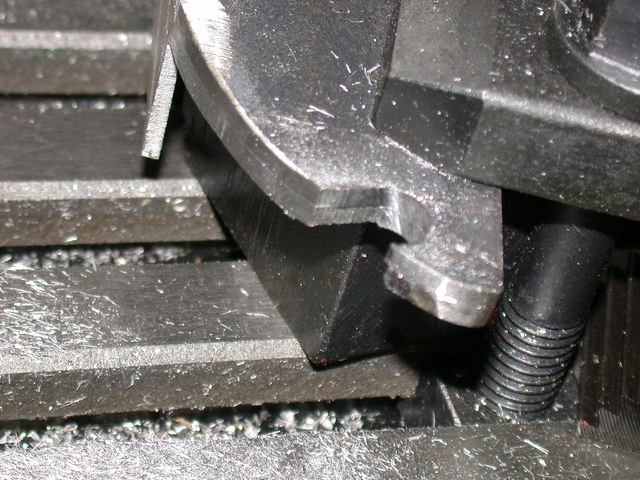

And then clamped the pieces together to mill out the slots for the bar. I figure it's always easier to match first, then cut! While I guess I could have measured with precision and done it in two operations, why would I bother?

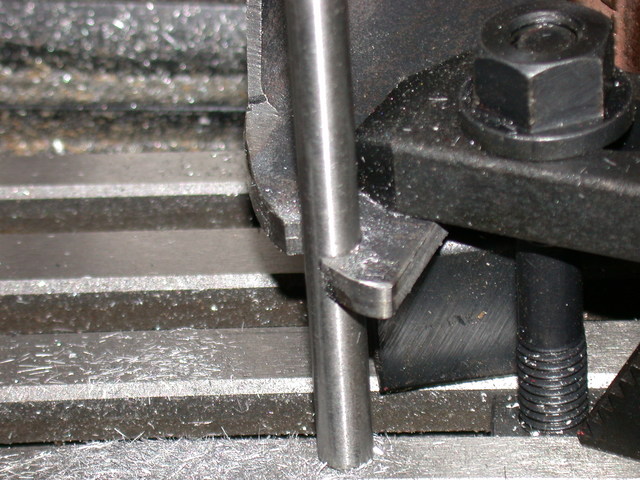

Some test fitting. This was before I was quite done, I milled the bracket slots a little bit deeper for clearance after this picture was taken. However, it does show how the brackets sit in the beak.

I drilled the mounting holes out (also on the mill, it makes one heckuva precision drill press) and captured the bar for another test fitting. You can see where the bar kind of interferes with the 'louvers' that cover up the horn. My choices were: Bigger bracket, mill the bar for clearance, or cut away some plastic. You'd better believe I'll be cutting plastic later in the project.

Top Page 1 Page 2 Page 3 Page 4 Page 5 Page 6 Page 7 Page 8 Page 9 Page 10